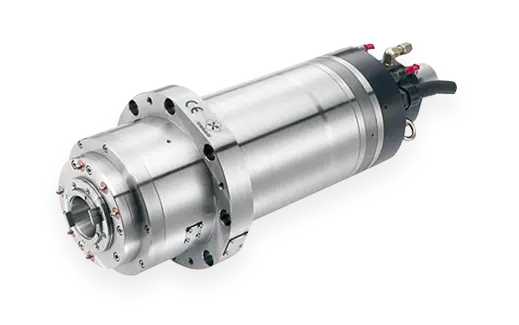

Grinding machine spindles

- Mainly applied to all kinds of surface grinding, internal hole grinding, external grinding, CNC grinding, etc.;

- It is suitable for high precision and ultra-precision machining of all kinds of axes or planes in the machining field;

- High rotary accuracy: the full runout of the bore of the shaft end of the grinding spindle is ≤1um, and the vibration of the spindle is ≤0.8mm/s, which has unparalleled high-precision characteristics;

- High speed: ultra-high speed and dynamic rigidity, providing strong support for high-speed and high precision machining of the grinding machine;

- High configuration: good expandability and compatibility, grinding spindle has good compatibility.

Grinding machine spindles

Spindle motor, also called high speed motor, refers to AC motors with more than 10,000 rpm/min. Mainly used in wood, aluminum, stone, hardware, glass, PVC and other industries, it has the advantages of fast rotation speed, small size, lightweight, low material consumption, low noise, low vibration, etc., more and more attention and application by related industries. In the modern society of high-speed progress of science and technology, due to the spindle motor is widely used, coupled with its meticulous workmanship, fast speed and higher processing quality of the motor, so that other ordinary motors can not meet the technical requirements of the spindle motor and play an important role in the process of industrial production, so in the country and even all over the world to the spindle motor is particularly favored.