TECO Motors And Drives

Founded in 1956 for motor production, TECO Electric & Machinery Co., Ltd. has evolved to a major business group, spanning heavy electric equipment, home appliances, information technology, communications, key electronic components and parts, infrastructural engineering, financial investment, dining, and services, with its business scope covering over 100 cities in more than 40 countries in the five major continents. In the future, in addition to continuing profound cultivation of its core businesses, TECO will develop in the direction of businesses with high added value, such as smart products and systematic solutions and dedicate to the expansion of hi-tech businesses, with the objective of “energy conservation, emissions reduction, Intelligence, and automation,” in order to build up a macro-perspective and high-quality world-class brand.

As an agent of TECO Electric Co., Ltd., we not only provide customers with TECO products, but also provide professional Industrial drive solution services.

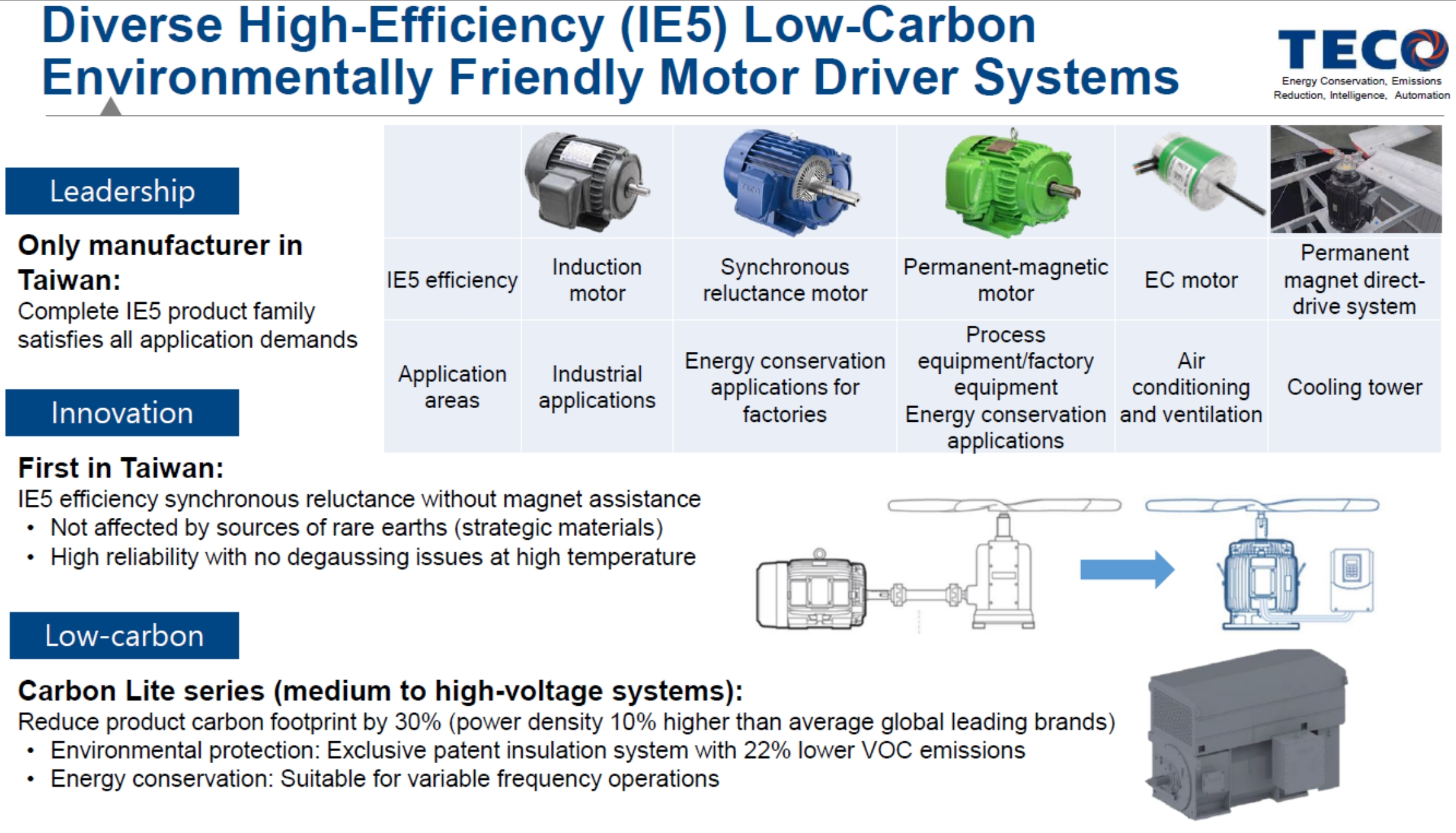

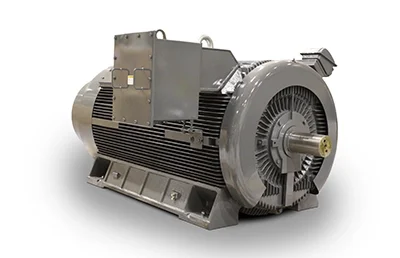

High Voltage Electric Motors

Key Features

TECO Squirrel Cage Motors are custom designed to each customer’s specific application. Because of their design versatility and high operating efficiencies, TECO motors are the logical choice for a multitude of industries including mining, oil & gas, petro-chemical, pulp and paper, electric utilities, water & waste, marine and steel.

TECO Squirrel Cage Motors are high performance machines with low maintenance costs. TECO uses the latest technologies to provide the best high efficiency motor solution throughout the power range of high voltage motors. This product line is ideal for operating in the toughest applications, which require increased strength and durability of motors.

Great design versatility to meet mechanical, electrical design and also be a drop and replacement machine for any existing application. TECO motors comply with all relevant international standards, incorporate the latest advances in insulation materials and are optimized for variable speed control.

From simple to complex designs, TECO Squirrel Cage Motors combine cost-efficient standardized designs and short lead times with safety, productivity, energy efficiency and reliability.

| Product Overview | |

| Output | 300 up to 15,000kW |

| Number of Poles: | 2 to 12 |

| Cooling method: | TEAAC & TEFC |

| Degree of Protection: | IP54 to IP66 |

| Frames: | 315 up to 1250 |

| Ambient temperature: | 40 °C |

| Elevation: | 1000m above sea level |

| Service factor: | 1.0 @ 40 deg C ambient |

| Mounting: | IM1001 |

| Voltages: | Up to 13,800V |

| Insulation Class: | “F” insulation (ΔT = 80K) |

| Continuous duty: | S1 |

| Design: | N |

| Thermal protection: | As per customer specification |

| Bearings: | Anti-friction Bearings , Sleeve bearings |

| Frame Material: | Fabricated Steeel |

| Color: | As per customer specification |

| Options Available | |

| Altitude above 1000 m (on request) | |

| Aluminum, copper or brass rotor | |

| Ambient temperature above 40 °C | |

| Base: rail, sliding base, extended feet, rebuilt feet, anchorage plate | |

| Bearing thermometer with gauge with/without contacts | |

| Cable gland in the terminal box entrance | |

| Class of insulation: H | |

| Classified area application: Ex-n, Ex-p | |

| Cooling: Forced ventilated, Air-to-water heat exchanger | |

| CT for differential and integral protection | |

| Electrically insulated bearing | |

| Encoder | |

| Grounding brush on drive end bearing | |

| Independent hydraulic oil circulation system for sleeve bearing | |

| Mountings: Vertical, Horizontal, Foot and Flange, Flange, | |

| NEMA Standard | |

| Noise suppressor in the air inlet and outlet | |

| Non-reversion ratchet | |

| Multiple accessory terminal boxes | |

| Power factor correction capacitors | |

| Protection against voltage surge: Lighting arrestors and Capacitors | |

| Service Factor: 1.15 | |

| Shaft: Special dimensions, double shaft end, tapered, hollow, special steel | |

| Signal transducer | |

| Sleeve bearing | |

| Special balance | |

| Special bearing (overdesigned) for axial or radial thrust | |

| Special painting | |

| Steel welded terminal box in different sizes, based on internal available space | |

| Temperature detector: Thermistor (PTC or NTC) | |

| Temperature detector: Thermostat (Bimetallic) | |

| Two energized power terminal boxes | |

| VFD application | |

| Vibration detector |

From 380V to 13,800V

TECO Squirrel Cage motors are ideal for operating in the toughest applications, which require increased strength and durability of motors.

Key Features

TECO Wound Rotor Motors are custom designed to each customer’s specific application. Because of their design versatility and high operating Efficiencies, TECO Wound Rotor Motors are the logical choice for a multitude of industries including mining, pulp and paper, electric utilities, sugar, water & waste, marine and steel.

TECO Wound Rotor Motors are built to last. Great design versatility to meet mechanical, electrical design and also be a drop and replacement machine for any existing application. Crown Series complies with all relevant international standards and incorporate the latest advances in insulation materials.

From simple to complex designs, TECO motors combine cost-efficient standardized designs and short lead times with safety, productivity, energy efficiency and reliability. TECO Wound Rotor Motors minimize mechanical stress at starting, increasing the lifetime of your driven equipment.

| Product Overview | |

| Output | 250 up to 15,000kW |

| Number of Poles: | 4 to 12 |

| Cooling method: | TEAAC & TEFC |

| Degree of Protection: | IP54 to IP65 |

| Frames: | 355 up to 1250 |

| Ambient temperature: | 40 °C |

| Elevation: | 1000m above sea level |

| Service factor: | 1.0 @ 40 deg C ambient |

| Mounting: | IM1001 |

| Voltages: | Up to 13,800V |

| Insulation Class: | “F” insulation (ΔT = 80K) |

| Continuous duty: | S1 |

| Design: | N |

| Thermal protection: | As per customer specification |

| Bearings: | Anti-friction Bearings , Sleeve bearings |

| Frame Material: | Fabricated Steeel |

| Color: | As per customer specification |

| Options Available | |

| Altitude above 1000 m (on request) | |

| Aluminum, copper or brass rotor | |

| Ambient temperature above 40 °C | |

| Base: rail, sliding base, extended feet, rebuilt feet, anchorage plate | |

| Bearing thermometer with gauge with/without contacts | |

| Brush Lifting System | |

| Cable gland in the terminal box entrance | |

| Class of insulation: H | |

| Cooling: Forced ventilated, Air-to-water heat exchanger | |

| CT for differential and integral protection | |

| Electrically insulated bearing | |

| Encoder | |

| Grounding brush on drive end bearing | |

| Independent hydraulic oil circulation system for sleeve bearing | |

| Mountings: Vertical, Horizontal, Foot and Flange, Flange, | |

| NEMA Standard | |

| Noise suppressor in the air inlet and outlet | |

| Non-reversion ratchet | |

| Multiple accessory terminal boxes | |

| Power factor correction capacitors | |

| Protection against voltage surge: Lighting arrestors and Capacitors | |

| Service Factor: 1.15 | |

| Shaft: Special dimensions, double shaft end, tapered, hollow, special steel | |

| Signal transducer | |

| Sleeve bearing | |

| Special balance | |

| Special bearing (overdesigned) for axial or radial thrust | |

| Special painting | |

| Steel welded terminal box in different sizes, based on internal available space | |

| Temperature detector: Thermistor (PTC or NTC) | |

| Temperature detector: Thermostat (Bimetallic) | |

| Two energized power terminal boxes | |

| Vibration detector |

From 380V to 13,800V

TECO Wound Rotor Motors Motors are designed to last.

Key Features

TECO has a complete range of Ex n, Ex e, Ex d, Ex de and Ex p hazardous area motors.

TECO uses the latest technologies to provide the best high efficiency motor solution

throughout the power range of low voltage and high voltage motors.

This product line is ideal for operating in the toughest applications, which require

increased strength and durability of motors.

| Product Overview | |

| Output | 185 up to 10000kW |

| Number of Poles: | 2 to 12 |

| Cooling method: | TEAAC &TEFC |

| Degree of Protection: | IP54 to IP66 |

| Frames: | 315 up to 1000 |

| Ambient temperature: | 40 °C |

| Elevation: | 1000m above sea level |

| Service factor: | 1.0 @ 40 deg C ambient |

| Mounting: | IM1001 |

| Voltages: | Up to 11000V |

| Insulation Class: | “F” insulation (ΔT = 80K) |

| Continuous duty: | S1 |

| Design: | N |

| Thermal protection: | As per customer specification |

| Bearings: | Anti-friction Bearings , Sleeve bearings |

| Frame Material: | Fabricated Steeel |

| Color: | As per customer specification |

Make it Safe with TECO!

Whatever your requirements, the TECO stands ready to assist you in developing a solution for Hazardous Area.

Key Features

TECO Open Drip Proof are custom designed to each customer’s specific application. Because of their design versatility and high operating efficiences, TECO Motors are the logical choice for a multitude of industries including mining, oil & gas, oetro-chemical, pul and paper, electric utilities, water & waste, marine and steel.

TECO Crown Series is built to last. Great design versatility to meet mechanical, electrical design and also be a drop and replacement machine for any existing application. Crown Series complies with all relevant international standards, incorporate the latest advances in insulation materials and are optimized for variable speed control.

From simple to complex designs, Crown series motors combine cost-efficient standardized designs and short lead times with safety, productivity, energy efficiency and reliability.

ODP Motors are normally used for indoor applications or when the customer wants to minimize the overall motor footprint. ODP can be normally one or two frames smaller compared to totally enclosed motors, bringing advantage not only in footprint, but also reducing overall weight and motor price.

| Product Overview | |

| Output | 300 up to 15,000kW |

| Number of Poles: | 2 to 12 |

| Cooling method: | Open self-ventilated |

| Degree of Protection: | IP20 to IP24 |

| Frames: | 355 up to 1000 |

| Ambient temperature: | 40 °C |

| Elevation: | 1000m above sea level |

| Service factor: | 1.0 @ 40 deg C ambient |

| Mounting: | IM1001 |

| Voltages: | Up to 13,800V |

| Insulation Class: | “F” insulation (ΔT = 80K) |

| Continuous duty: | S1 |

| Design: | N |

| Thermal protection: | As per customer specification |

| Bearings: | Anti-friction Bearings , Sleeve bearings |

| Frame Material: | Fabricated Steeel |

| Color: | As per customer specification |

| Options Available | |

| Altitude above 1000 m (on request) | |

| Aluminum, copper or brass rotor | |

| Ambient temperature above 40 °C | |

| Base: rail, sliding base, extended feet, rebuilt feet, anchorage plate | |

| Bearing thermometer with gauge with/without contacts | |

| Cable gland in the terminal box entrance | |

| Class of insulation: H | |

| Cooling: Forced ventilated, Self-ventilated by ducts, Air-to-water heat exchanger, WPI, WPII | |

| CT for differential and integral protection | |

| Electrically insulated bearing | |

| Encoder | |

| Grounding brush on drive end bearing | |

| Independent hydraulic oil circulation system for sleeve bearing | |

| Mountings: Vertical, Horizontal, Foot and Flange, Flange, | |

| NEMA Standard | |

| Noise suppressor in the air inlet and outlet | |

| Non-reversion ratchet | |

| Multiple accessory terminal boxes | |

| Power factor correction capacitors | |

| Protection against voltage surge: Lighting arrestors and Capacitors | |

| Service Factor: 1.15 | |

| Shaft: Special dimensions, double shaft end, tapered, hollow, special steel | |

| Signal transducer | |

| Sleeve bearing | |

| Special balance | |

| Special bearing (overdesigned) for axial or radial thrust | |

| Special painting | |

| Steel welded terminal box in different sizes, based on internal available space | |

| Temperature detector: Thermistor (PTC or NTC) | |

| Temperature detector: Thermostat (Bimetallic) | |

| Two energized power terminal boxes | |

| VFD application | |

| Vibration detector |

From 380V to 13,800V

TECO Open Drip Proof Motors are compact and design for indoor and outdoor application

Key Features

TECO Synchronous Motors and Generators provide superior value in terms of proven reliability, low maintenance performance and long life in any application.

Our synchronous machines offer numerous benefits including:

Constant-speed operation

High efficiency ratings

Low inrush currents

Leading power factor (for corrective KVA capability)

These features make them the optimal choice for many industrial drive applications.

Power factor improvement is one of the most attractive considerations in selecting a synchronous machine. Synchronous motors operate at leading power factors and are available with rated power factors ranging from unity to leading. Thus they can produce substantial savings by supplying kvar’s to counteract lagging power caused by other inductive loads.

Application

TECO Synchronous Machines are customized to the specific requirements of each application. Because of their unique features, high operating efficiencies, and adaptability to all working environments, synchronous motors and generators are the logical choice for a multitude of industries. These include pulp and paper processing, electric utility, marine, water and wastewater treatment, chemical and petrochemical, steel, mining, cement, and air separation.

Synchronous machines can be found wherever there is a demand for highly efficient, cost-effective, dependable machines. They are frequently used for rolling, ball and sag mills, chippers, mixers, pulp refiners, pumps, fans, and compressor (reprocating and centrifical) drives.

They can be furnished with adjustable frequency drives (PWM, LCI, and Cyclo-converter) or soft starters for speed regulation.

With all of the advancements made in adjustable frequency drive technology, the variable speed synchronous motor is a logical choice for applications requiring high torque at low speed with a high-speed range.