MAX-E2/841™ NEMA Premium Efficiency – Inverter, Severe Duty, TEFC

Totally Enclosed Fan Cooled, [HB], [HB_C], [HBV_C]

AEHH8B, NEMA PREMIUM [HB]

AEHH8BCF, NEMA PREMIUM, FOOTED C-FACE (1 HP – 100 HP) [HB_C]

AEUH8BDC, NEMA PREMIUM, ROUND BODY C-FACE (1 HP – 100 HP) [HBV_C]

| HP | 1 HP through 500 HP |

| Speed | 3600, 1800, 1200, 900 RPM |

| Voltage | 460V |

| Frequency | 60 Hz |

MAX-E2/841™ NEMA Premium Efficiency – Inverter, Severe Duty, TEFC

MAX-E1® motors are TOTALLY ENCLOSED FAN COOLED, squirrel-cage induction motors that are designed, manufactured and tested to meet or exceed the latest NEMA, IEEE, and other international standards. All motors are CSA certified for Class I, Division II, Groups B, C, and D; temperature code T3C and have a non-sparking, non-static fan.

These motors are suitable for severe applications in environments with excessive dirt, dust and/or moisture.

The unique design, first-grade material and excellent workmanship of the MAX-E1® make TECO-Westinghouse motors last much longer and provide cost-efficent operation.

ELECTRICAL DESIGN:

- 1 – 500 HP; 2, 4, 6 pole

- 3600, 1800, 1200 RPM

- 3 Phase, 60 Hz, 460V

- Motors can be re-rated for 380, 400 and 415 VAC at 50 Hz.

- Designed to meet NEMA MG-1, MG-13, and IEEE 841

- Stock available in 460V; other voltages available, contact factory for details.

- Premium Efficiency; meets or exceeds the requirements of NEMA MG1-12.60, NEMA Premium Efficiency, table12-12, and Canadian Federal Efficiency Levels defined in CSA C390-93. Full load efficiency of all ratings is certified under the EEV Program of the CSA.

- UL recognized, Class F, non-hygroscopic insulation system with Inverter duty magnet, index, heavy heat resistance enameled copper wire insures longer winding life and reliability.

- CSA certified for Class I, Division 2, Group B, C & D; Class II, Division 2, Group F & G. Non-sparking,non-static fan

- Class B temperature rise, 80°C rise by resistance method at 1.0 S.F.; 90°C rise at 1.15 S.F. Class F insulation with Phenolic Alkyd Resin Varnish – 2 dips and bakes

- Three leads, solderless lug terminals.

- Meets IEEE 45 Marine Duty and ABS Type Certified

- Meets GM 7E-TA specifications.

- Suitable for Inverter Duty applications – 20:1 constant torque and 60:1 variable torque applications.

- 350 HP and larger are 3:1 CT.

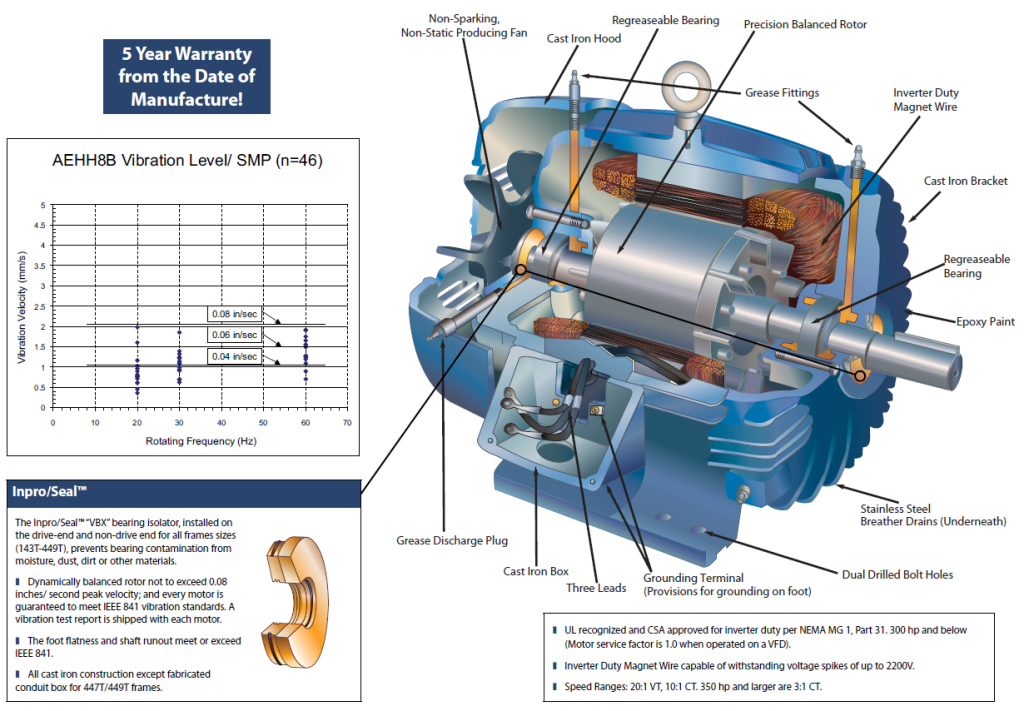

MECHANICAL DESIGN:

- NEMA Design B torques as a minimum

- Bearing temperature rise is below 45°C for all 4P and 6P ratings; 50°C for all 20 motors.

- Sound pressure levels are below 85 dBA providing quiet operation.

- Full cast iron construction: frame, brackets, fan cover, and conduit box.

- Frame provided with two threaded drain holes c/w drain plugs; a drilled and tapped hole for a ground lug is provided on the frame.

- Corrosion-resistant cast iron conduit box with IP65/B66 rated protection has twice the volume required by NEMA. The conduit box is fully gasketed with NPT threaded conduit entry.

- Regreaseable bearing construction with inner bearing caps prevent bearing contamination.

- Non-sparking plastic or bronze fan.

- All interior exposed surfaces including stator coil ends and rotor surfaces are cleaned and coated with moisture resistant varnish. The exterior is painted with zinc-chromate epoxy base with a blue finish.

- Stainless steel hardware and nameplate.

- Vibration will not exceed 0.08 inches per second.

- Optimum rotor design allows for industry leading locked rotor torque per locked rotor amp levels

- Dual Drilled Feet – longer frames (i.e. 145T drilled also for 143T) through 449T Frames only

Features

- Three Phase, 60 Hz, 1.15 Service Factor (Continuous); 50 Hz, 1.0 Service Factor (Continuous)

- CSA Certified for Class I, Div. 2, Groups B, C, D – Temp Code T3 Minimum

- CSA Certified for Class II, Div. 2, Groups F & G – Temp Code T3 Minimum (Frame 444T and Above)

- Meets or Exceeds IEEE 841 Standards

- Meets IEEE 45 Marine Duty and ABS Design Assessment up to 500 HP(2,4,6 pole only)

- Extended Warranty – 60 Months from Date of Manufacture

- Class F Insulation

- Class B Temperature Rise

- NEMA Design B Torques as a Minimum; Various Ratings also Meet Design C

- Cast Iron Frame, End Brackets & Fan Cover and Main Conduit Box

- Grounding Terminal Inside Main Conduit Box with additional Foot Grounding Provision

- Oversized Main Conduit Box Rotatable in 90 Degree Increments – F1 Mounted

- Designed for 50˚C Ambient Temperature

- Designed for 3300 ft. Elevation

- Bi-Directional Rotation; Except 2 Pole “Hybrid” and F# 5000 and Larger Ratings are Counter-Clockwise facing the DE

- 1045 Carbon Steel Shaft

- Aluminum Die Cast Squirrel Cage Rotor Construction for F# 140T – 449T Copper/Copper Alloy Rotor Construction for F# 5000 and Larger

- Paint System: 2 Part Epoxy

- Paint Color: Blue – Munsell 5PB 3/8

- High Quality Ball (or Roller) Bearings Regreasable with Mobil Polyrex™ EM

- Automatic Grease Discharge Fittings

- VBXX INPRO™ Seals Installed on Both Ends

- Stainless Steel Nameplate and Hardware

- Stainless Steel Automatic Breather Drain

- New Dual Column Design Nameplate as Standard (60/50 Hz)

- Suitable for Inverter Use per NEMA MG-1.4.4.2, Part 31

- Inverter Duty Speed Range: 20:1 Variable Torque, 10:1 Constant Torque (350 HP and Larger are 3:1 Constant Torque)

- Motors are U.L. Recognized, CSA Approved

- 3 Leads Only

- Dual Drilled Feet Available on Most Ratings – Longer Frames (i.e. 145T Drilled also for 143T)

- Vibration Not to Exceed 0.08 Inches Per Second

- Noise Level Not to Exceed 85 dB(A) at 1 Meter Unloaded

Applications

Fans & Blowers , Pumps, Crushers, Compressors, Mixers, Conveyors, Any Severe Duty/ Petro-Chem/Marine Duty