MAX-E1® Family NEMA Premium Efficiency

Totally Enclosed Fan Cooled, [EP], [E], [E]_C], [EPV_C]

AEHH8N, NEMA PREMIUM (1 HP – 500 HP) [EP]

AEHE, HIGH EFFICIENCY [E]

AEHH8NCF, NEMA PREMIUM, FOOTED C-FACE (1 HP – 300 HP) [EP_C]

AEUH8NDC, NEMA PREMIUM, ROUND BODY C-FACE (1 HP – 100 HP) [EPV_C]

| HP | 3/4 HP through 800 HP |

| Speed | 3600, 1800, 1200, 900 RPM |

| Voltage | 230/460V (usable on 208V) |

| Frequency | 60 Hz. |

MAX-E1 Family NEMA Premium Efficiency

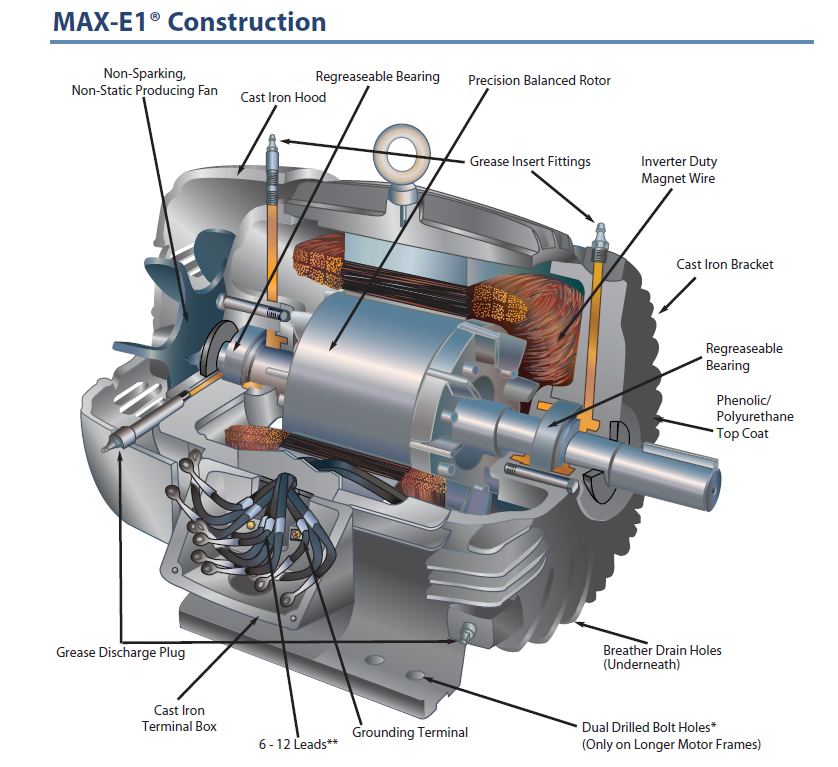

MAX-E1® motors are TOTALLY ENCLOSED FAN COOLED, squirrel-cage induction motors that are designed, manufactured and tested to meet or exceed the latest NEMA, IEEE, and other international standards. All motors are CSA certified for Class I, Division II, Groups B, C, and D; temperature code T3C and have a non-sparking, non-static fan.

These motors are suitable for severe applications in environments with excessive dirt, dust and/or moisture.

The unique design, first-grade material and excellent workmanship of the MAX-E1® make TECO-Westinghouse motors last much longer and provide cost-efficent operation.

POWER SUPPLY:

MAX-E1® motors will operate satisfactorily on voltages

within +/- 10% fluctuation of rated voltages; or frequency

within +/- 5% combined fluctuation, not to exceed 10%.

AMBIENT TEMPERATURE:

Standard ambient temperature is – 20C to 40oC (104F),

however, motors with 1.15 service factor can be operated at an

ambient temperature up to 50C (122F) at a 1.0 service factor.

For lower or higher ambient temperature applications, refer

to TECO-Westinghouse for modification options.

ALTITUDE:

Standard MAX-E1® motors can operate at all altitudes up to

9,900 feet (3,000 meters) with a service factor of 1.15.

Motors having a service factor of 1.0 can operate at altitudes

up to 3,300 feet (1,000 meters).

MODIFICATIONS AVAILABLE:

- Class F And H Insulation

- Space Heaters

- Thermal Protection

- Windings

- Bearings

- Special Paint Finish

- Double End Shaft or Special Shaft Dimensions

- 50 Hz Operation

- Shaft Grounding

- Insulated Bearings

- Blower Kits for VFD Service

- Encoders

- Mounting Flange Options: C or D Design

- Terminal Box Position: F1 or F2

- Contact TECO-Westinghouse for Additional Modifications

Features

- Three Phase, 60 Hz, 1.15 Service Factor (Continuous); 50 Hz, 1.0 Service Factor (Continuous)

- CSA Certified for Class I, Div. 2, Groups B, C, D – Temp Code T3 Maximum

- CSA Certified for Class II, Div. 2, Groups F & G – Temp Code T3 Maximum (Frame 444T and Above)

- Class F Insulation

- Class B Temperature Rise

- NEMA Design B Torques as a Minimum; Various Ratings also Meet Design C

- Cast Iron Frame, End Brackets & Fan Cover and Main Conduit Box

- Grounding Terminal Inside Main Conduit Box

- Oversized Main Conduit Box Rotatable in 90 Degree Increments – F1 Mounted

- Designed for 40˚C Ambient Temperature

- Designed for 3300 ft. Elevation

- Bi-Directional Rotation; Except 2 Pole “Hybrid” and F# 5000 and Larger Ratings are Counter-Clockwise facing the DE

- 1045 Carbon Steel Shaft

- Aluminum Die Cast Squirrel Cage Rotor Construction for F# 140T – 449T Copper/Copper Alloy Rotor Construction for F# 5000 and Larger

- Paint System: Phenolic Rust Proof Base Plus Polyurethane Top Coat

- Paint Color: Light Gray – Munsell N5.0

- Double Shielded Bearings Pre-Packed with MULTEMP SRL for F# 140T – 280T (Non-regreasable)

- High Quality Ball (or Roller) Bearings Regreasable with Mobil Polyrex™ EM Grease for F# 280TS and Larger

- Automatic Grease Discharge Fittings on Regreasable Models

- Labyrinth Type Metal Flinger on Both Ends for F# 280TS and Larger

- Cast Iron Inner and Outer Bearing Caps for F#280TS and Larger

- Stainless Steel Nameplate

- New Dual Column Design Nameplate as Standard (60/50 Hz)

- Suitable for Inverter Duty (PWM – Pulse Width Modulation) per NEMA MG-1, Part 30

- Inverter Duty Speed Range: 20:1 Variable Torque, 10:1 Constant Torque (350 HP and Larger are 3:1 Constant Torque)

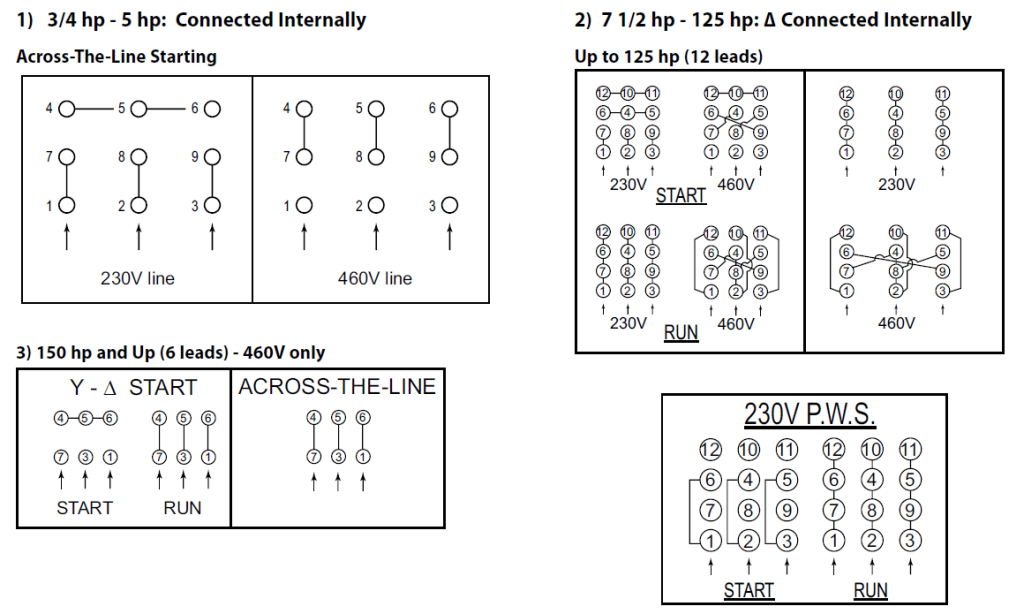

- 9 Leads for 5 HP and Smaller;

- 12 Leads for 7.5 HP to 125 HP;

- 6 Leads for 150 HP and Larger

- Motors are U.L. Recognized, CSA Approved and CE Marked

- Dual Drilled Feet Available on Most Ratings – Longer Frames (i.e. 145T Drilled also for 143T)

- Insulated Non-Drive End Bearing on 2-Pole Motors 600 HP and Larger

- Rubber Dust Flinger on Drive-End for F# 140T – 280T

Applications

Fans & Blowers , Pumps, Crushers, Compressors, Mixers, Conveyors, Any Severe Duty/ Petro-Chem/Pulp & Paper Application

MAX-E1 CONNECTION DIAGRAMS