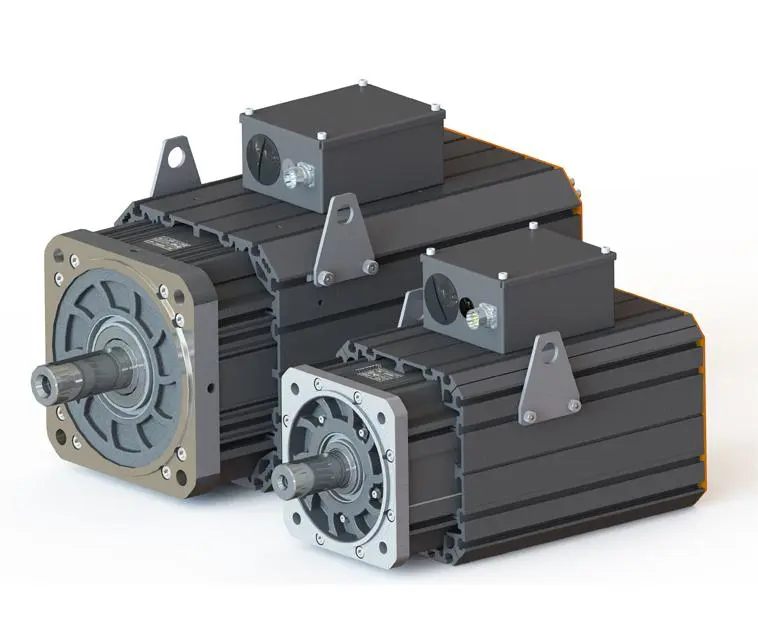

Permanent Magnet Servo Motors

why choose us

DJ Edrive is a professional industrial drive system solution provider, dedicated to providing high-efficiency permanent magnet motor drive solutions for industrial customers around the world.

what we do

Our Best Solutions

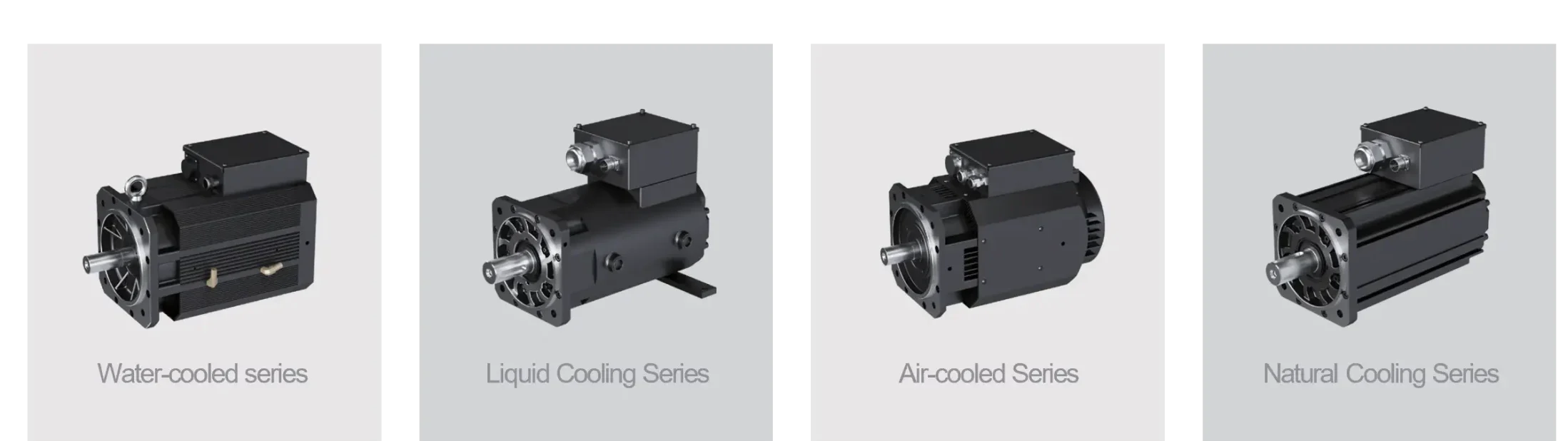

Permanent Magnet Servo Motors

Permanent magnet synchronous servo motor, a kind of AC permanent magnet servo motor, is widely used in the field of small and medium-capacity high-precision transmission to generate magnetic field by adding permanent magnets to the rotor. Due to the inherent properties of permanent magnet materials, it no longer needs external energy to establish a very strong permanent magnetic field in the space around it. This simplifies the motor structure and saves energy.

Our company specializes in the research and production of high-efficiency permanent magnet synchronous motors that reach the highest Level 1 energy efficiency standards, in compliance with the latest national requirements for motor efficiency. By phasing out outdated and inefficient equipment, we have been actively promoting motor efficiency upgrades.

Not requiring commutators and brushes reduces maintenance costs. Pitch motors offer a wide selection range and high control precision. With a high corrosion resistance rating and special internal coatings, it ensures the wind turbine pitch system’s safe, reliable, and long-term operation in various harsh environments. Permanent magnet synchronous servo motor characteristics:

- High power factor and high efficiency;

- Simple structure, reliable operation;

- Small volume, light weight, low loss.

Manufacturing Capabilities

The company has introduced advanced permanent magnet synchronous motor production lines from both domestic and international sources and has implemented the ISO9001 quality management system.

The production facilities are equipped with

state-of-the-art equipment. The stator assembly line is equipped with a fully automatic vacuum impregnation machine and an automatic stator comprehensive testing instrument, among other automated devices.

The rotor assembly line is equipped with a

Schenck dynamic balancing machine from Germany, and the final assembly line is an automated production line. Manual workstations are equipped with high-precision torque wrenches to ensure the precise placement of every bolt.

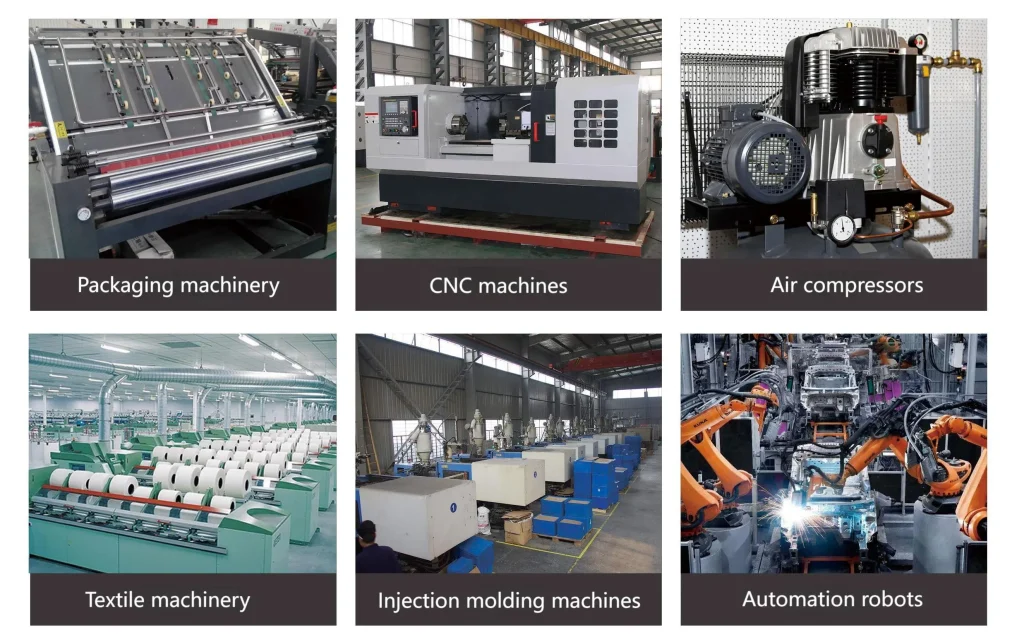

applications

Our Customers