Permanent Magnet Motors

IE5 permanent magnet motors

why choose us

DJ Edrive is a professional industrial drive system solution provider, dedicated to providing high-efficiency permanent magnet motor drive solutions for industrial customers around the world.

what we do

Our Best Solutions

Permanent Magnet Motors

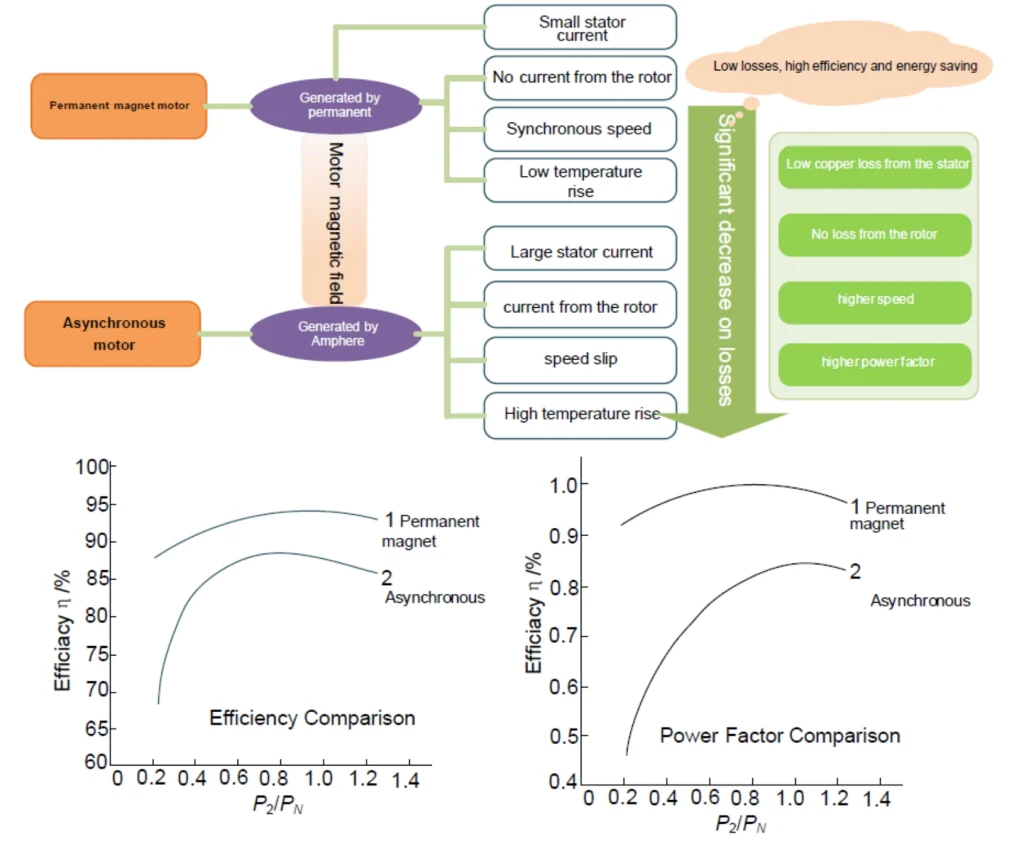

Permanent magnets are predominantly fabricated from rare-earth materials which produce a consistent magnetic field. With their integrated magnets, PM motors do not require an electrical current to generate a magnetic field in the rotor, which sets them apart from conventional induction motors. This principle results in the higher efficiency of these types of motors.

Rare-earth magnets are the driving force behind the high efficiency levels of PM motors. These rare-earth magnets have magnetic properties that far surpass those of conventional ferrite magnets. They provide a higher power density, allowing for smaller, lighter and more efficient motors than those using ferrite magnets.

These motors comply with the IE5 efficiency class – the pinnacle of internationally recognized efficiency levels and even higher.

From individual applications up to large-scale infrastructure projects in industry, the unparalleled efficiency, compactness and superior performance of PM motors make them the obvious choice.

PM motors are suitable for applications such as material handling, HVAC, water and wastewater, automotive, food processing, textiles – to name just a few. PM motors are not limited to conventional applications, but excel in other demanding use cases, especially where constant torque is required or high power density is a decisive factor.

The wide field of applications that can be addressed includes the following, for example: Pumps, Fans, Blowers, Compressors, Cranes, Conveyor belts, Extruders, Mixers.

advantages of Permanent Magnet Motors

Simple Structure, High Reliability, Maintenance-Free

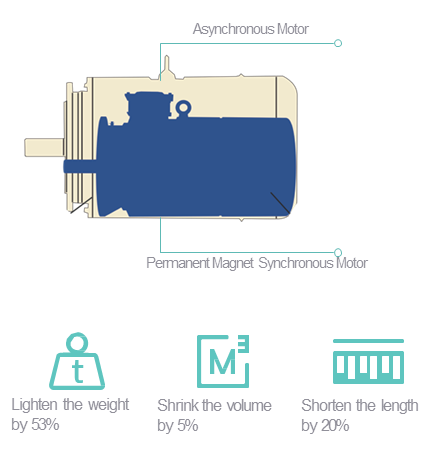

The advantages of a permanent magnet synchronous motor (PMSM) compared to an asynchronous motor include smaller size, lighter weight, lower losses, higher efficiency, higher torque-to-inertia ratio, measurable rotor parameters, and good controllability. Its vector control system can achieve high precision, high dynamic performance, and a wide range of speed or position control, making it widely used in various energy-efficient, high-efficiency, high-precision control, and low-noise motor applications.

High Efficiency, Low Energy Consumption

After embedding permanent magnets on the rotor of a permanent magnet synchronous motor, the rotor’s magnetic field is established by the permanent magnets. During normal operation, the rotor synchronously rotates with the stator’s magnetic field, resulting in no induced rotor current. This eliminates rotor resistance losses, which alone can improve motor efficiency by 5-10%. Due to the absence of induced rotor current excitation in permanent magnet motors, the stator winding may behave as a purely resistive load, resulting in a power factor close to 1 for the motor.

Comparison of PM motor and Asynchronous motor

Manufacturing capabilities

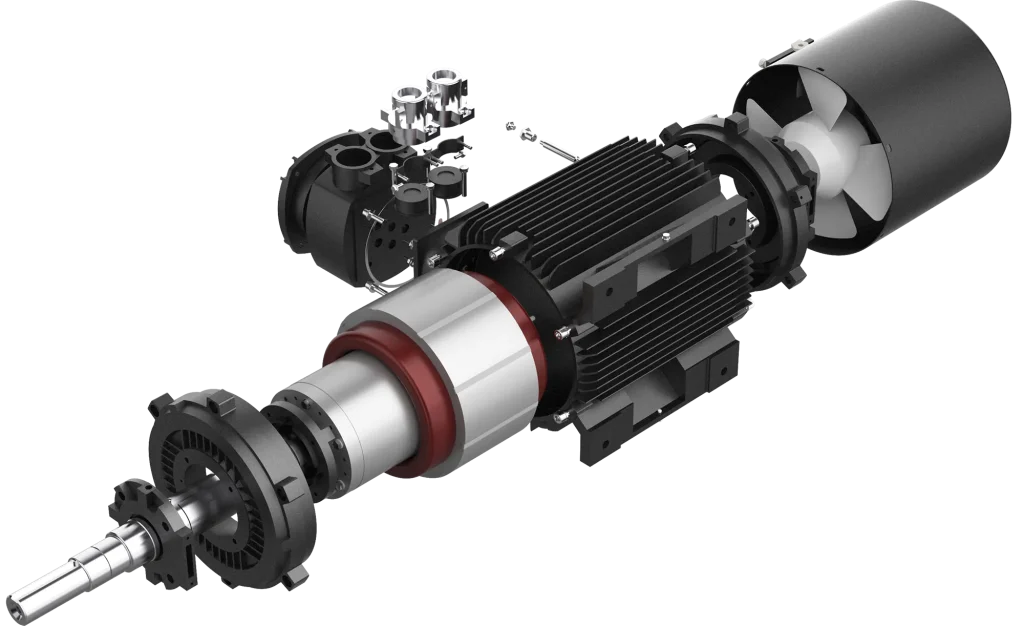

The company has introduced advanced permanent magnet synchronous motor production lines from both domestic and international sources and has implemented the ISO9001 quality management system.

The production facilities are equipped with

state-of-the-art equipment. The stator assembly line is equipped with a fully automatic vacuum impregnation machine and an automatic stator comprehensive testing instrument, among other automated devices.

The rotor assembly line is equipped with a

Schenck dynamic balancing machine from Germany, and the final assembly line is an automated production line. Manual workstations are equipped with high-precision torque wrenches to ensure the precise placement of every bolt.

Product Certification

The comprehensive testing laboratory has gotten CNAS certification.

Our frequency conversion integrated motor products have successfully gotten LVD (safety), EMC tests, and obtained CE

certification.

Frequency conversion integrated motor product series meet the Grade 1 energy efficiency requirements of GB 30253-2013 “Energy Efficiency Limits and Energy Efficiency Grades of Permanent Magnet Synchronous Motors” which is equivalent to IE5.

Our Customers

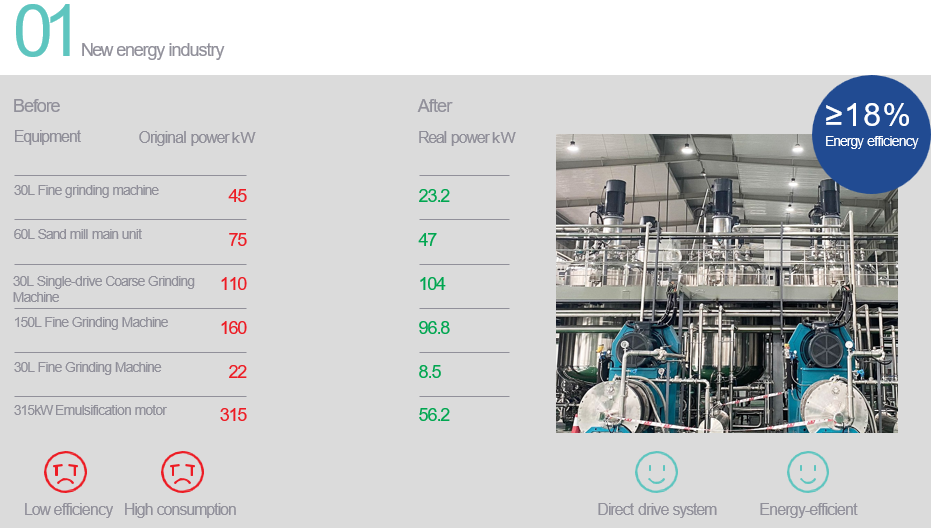

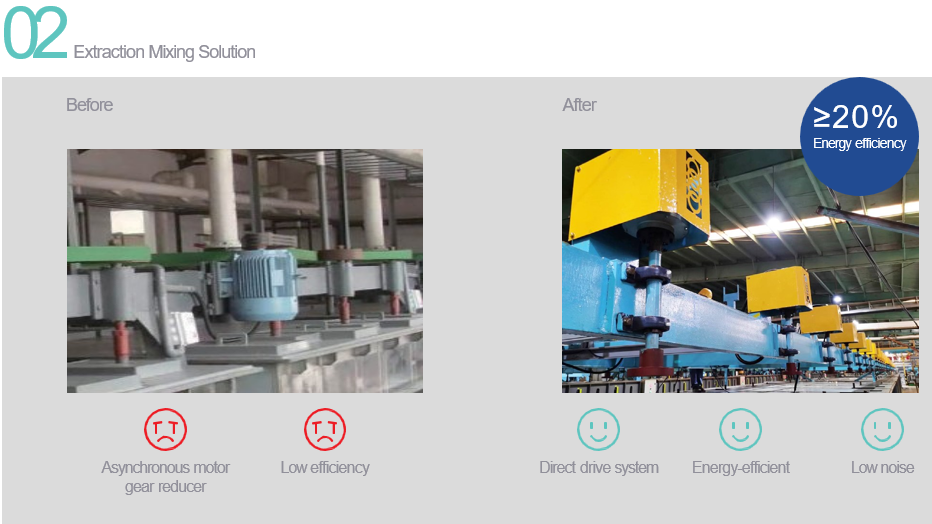

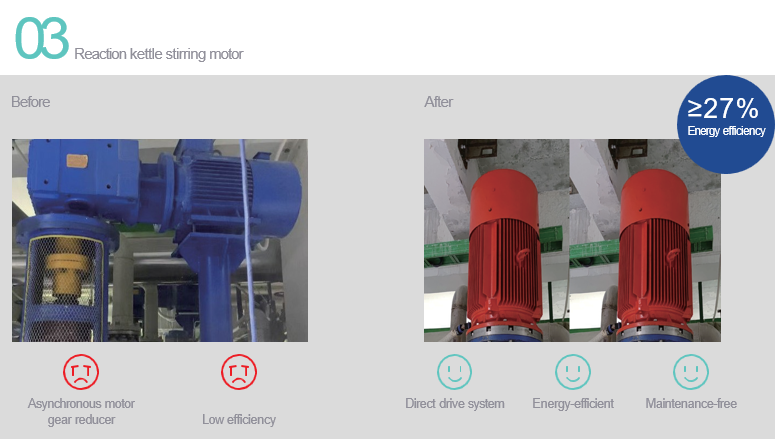

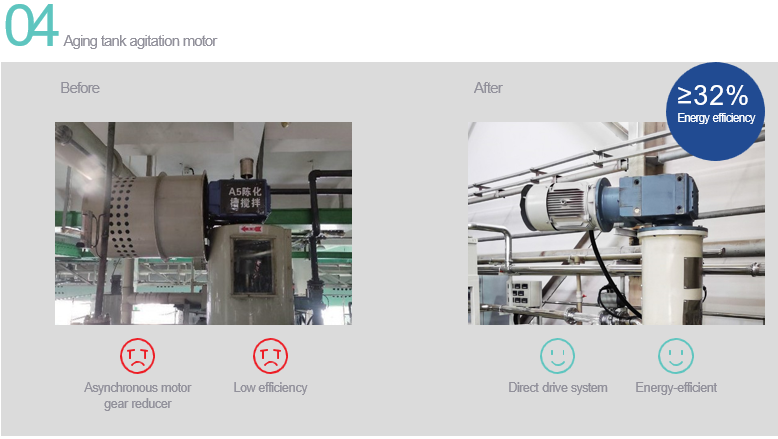

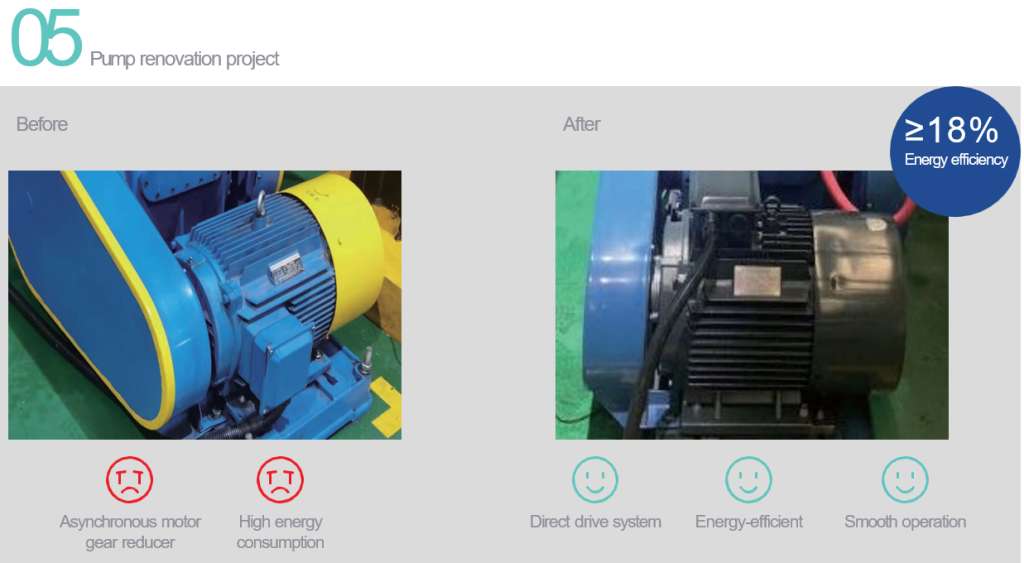

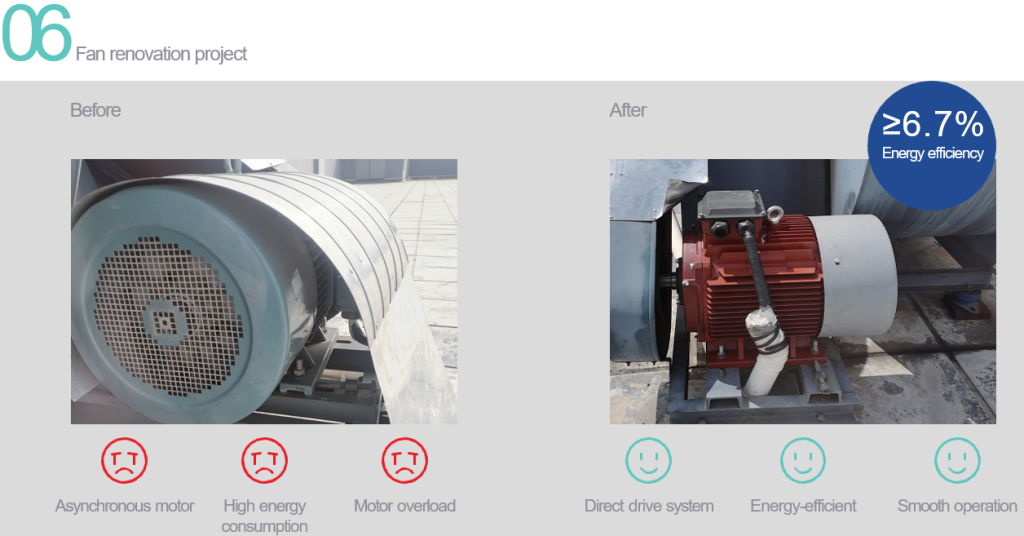

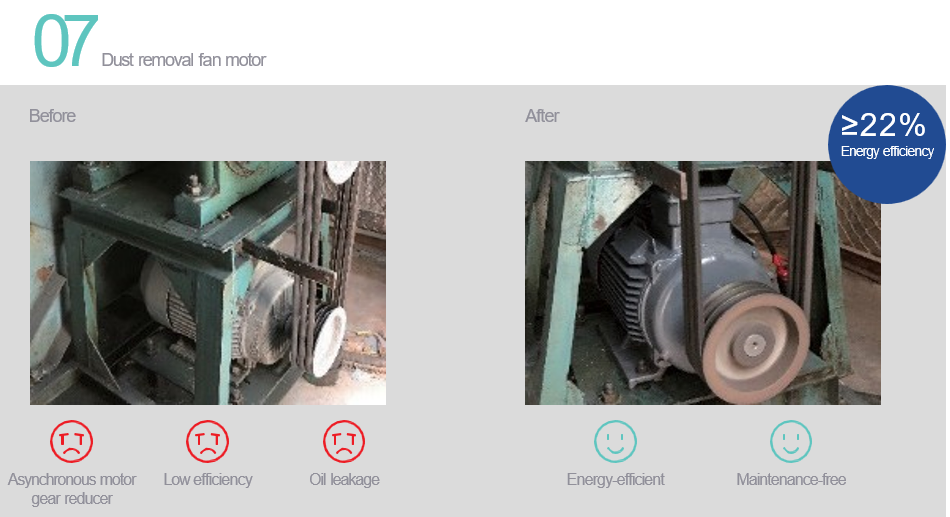

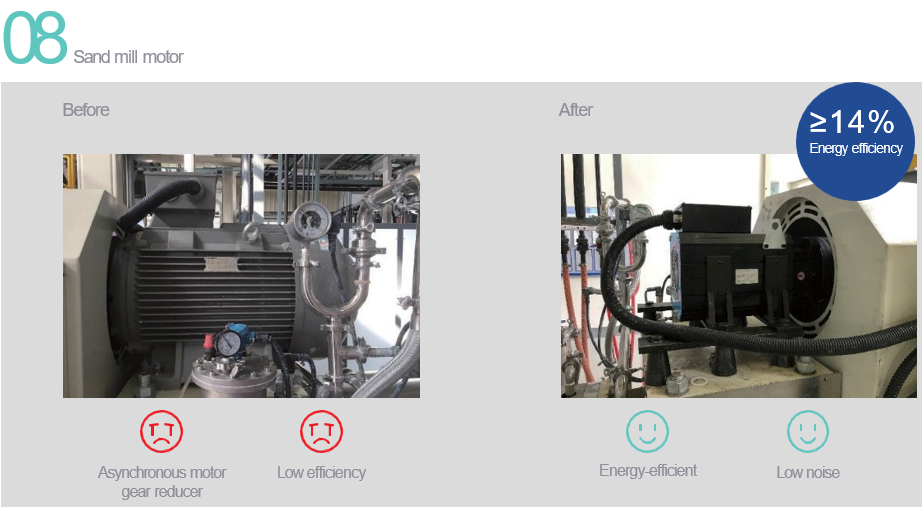

case Studies