Permanent Magnet Electric Spindles

why choose us

DJ Edrive is a professional industrial drive system solution provider, dedicated to providing high-efficiency permanent magnet motor drive solutions for industrial customers around the world.

what we do

Our Best Solutions

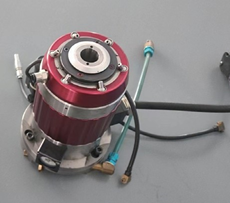

Permanent Magnet Electric Spindles

The company’s “Rare Earth Synchronous Motor Technology” enables the electric spindle to provide a strict constant torque output within the zero-speed to rated speed range and achieve a wide constant power variable speed range from rated speed to maximum speed. It is particularly suitable for low-speed heavy cutting and high-speed precision cutting.

The wide constant power variable speed range has exceeded a 1:6 ratio, making it suitable for many high-speed, high-efficiency machining applications, primarily used in the field of machine tools commonly known as industrial mothership.

- No induced current in the rotor, low heat generation, therefore low thermal deformation and high precision;

- Constant torque characteristics at rated speed, benefit from the characteristics of permanent magnets, the same volume under the output power and torque increased by 50% or more;

- No need for excitation current, lower loss, and unique hard torque characteristics, higher resistance to load fluctuations;

- Expanding the range of low-speed power cutting and high-speed precision cutting applications for machine tools.

| Series Model | Unit | Drilling and tapping machine spindle | Lathe motor spindle | Milling machine spindle | Machining center electric spindle |

| Toolholder specifications | BT30 | A2-5、6 | BT30 | BT30、40 | |

| Rated torque | N.m | 6 | 15、53.2、96 | 5.3 | 11.5、25、29 |

| Rated torque | |||||

| Maximum torque | N.m | 6 | 6 | 7.8 | 17、29、50 |

| Rated speed | rpm | 12000 | 3000、1350、1100 | 12000 | 4000、5000、8000 |

| Maximum speed | rpm | 24000 | 3000、7000、4500 | 24000 | 21000、21000、18000 |

| Voltage level | V | 380 | 380 | 380 | 380 |

| Rated current | A | 22 | 15、30、45 | 22 | 20、33、28 |

| Maximum current | A | 40 | 23、50、100 | 33 | 32、70、55 |

| Power | kW | S1:7.5 S6:15 | S1:4.75、7.5、11 S6:11、11、18 | S1:6.7 S6:10 | S1:4.8、13、12 S6:7.5、18、20 |

Advantages

Low-speed powerful cutting

High starting torque, capable of outputting all torque at 0 speed, with optimal performance achieved in seconds, expanding the application range of machine tools for low-speed powerful cutting and high-speed precision cutting.

High precision cutting

The vibration is as low as 0.3mm/s, and the precision of the shaft diameter jumping end reaches 1um, improving the surface processing accuracy of the workpiece.

Manufacturing capabilities

The company has introduced advanced permanent magnet synchronous motor production lines from both domestic and international sources and has implemented the ISO9001 quality management system.

The production facilities are equipped with

state-of-the-art equipment. The stator assembly line is equipped with a fully automatic vacuum impregnation machine and an automatic stator comprehensive testing instrument, among other automated devices.

The rotor assembly line is equipped with a

Schenck dynamic balancing machine from Germany, and the final assembly line is an automated production line. Manual workstations are equipped with high-precision torque wrenches to ensure the precise placement of every bolt.

Applications

The application fields of electric spindles encompass various industrial and manufacturing processes that require high-speed and high-precision rotational power. They contribute to enhancing production efficiency, precision, and quality, thus finding extensive use across diverse industries.

Engraving and milling machines, drilling and tapping machines, machining center machines, boring machines, tool grinding machines, internal cylindrical grinding machines, external cylindrical grinding machines, internal and external cylindrical grinding machines, bearing grinding machines, thread grinding machines, deep hole internal cylindrical grinding machines, guideway grinding machines, surface grinding machines and so on.

Repair Cases

Our Customers