Difference between servo motor and torque motor

Servo motor characteristics and principles

Servo motor can be torque, position, speed and other three modes for the control direction of the motor, can be used in a closed-loop control mode, the control accuracy is high; its main features are: when the signal voltage is zero when there is no self-rotation phenomenon, the speed of the torque with the increase and the uniform decline in rotational inertia is small, can be used for positioning.

Servo motor can make the control speed, position accuracy is very accurate, can be converted into voltage signal torque and speed to drive the control object. Servo motor rotor speed is controlled by the input signal, and can respond quickly, in the automatic control system, used as an executive element, and has a small electromechanical time constant, high linearity, starting voltage and other characteristics, can be converted to the received electrical signal into an angular displacement on the motor shaft or angular velocity output. Divided into two categories of DC and AC servo motors, its main feature is that there is no self-rotation phenomenon when the signal voltage is zero, and the rotational speed decreases uniformly with the increase of torque.

Characteristics and principle of torque motor

Torque motor is a motor with torque as the direction of control, adopting open-loop control, it is a kind of special motor with soft mechanical characteristics and wide speed regulation range, with low rotational speed, large torque, strong overload capacity, fast response and good characteristic linearity. Its main features are: it has soft mechanical characteristics and can be blocked. When the load torque increases, it can automatically reduce the speed and increase the output torque at the same time. When the load torque is a certain value, changing the motor terminal voltage can adjust the speed.

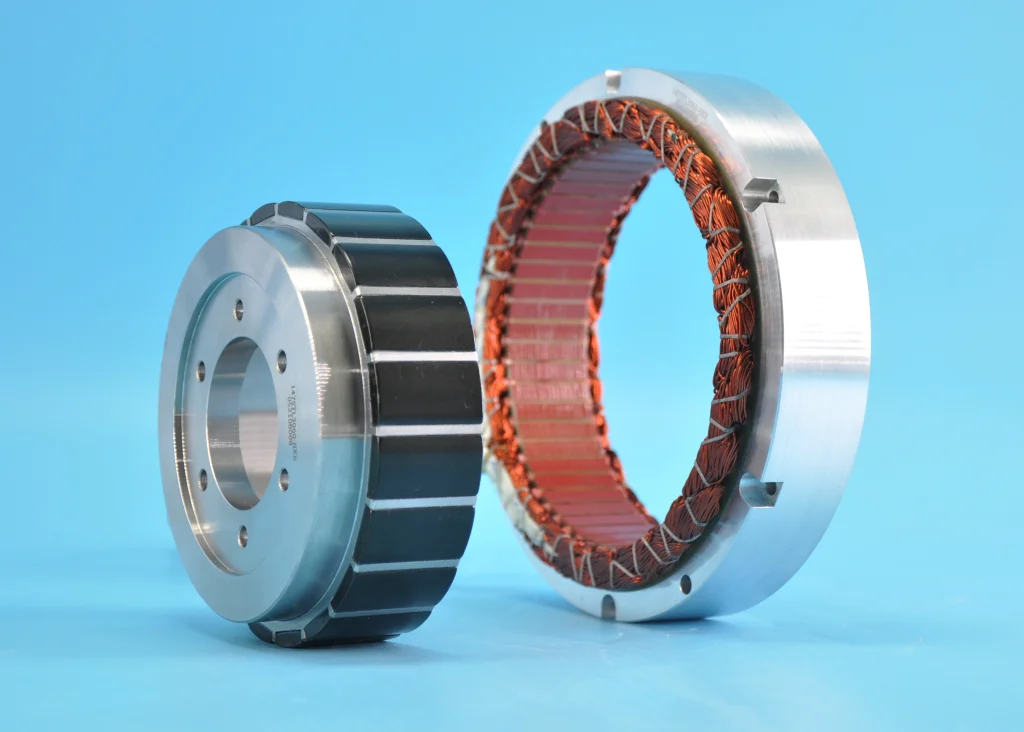

Torque motor is a special type of brushless permanent magnet synchronous motor. Since the load is directly connected to the rotor without any transmission parts, the torque motor is a direct-drive motor. Publication “Mechanical Engineering Literature”, the gas station for engineers.

A torque motor can be thought of as a linear motor rolled into a circle, or a conventional servomotor with a large number of pole pairs. Because of the large number of pole pairs, a conventional torque motor can provide high torque at medium speeds. Another important feature is the compactness of the motor, which consists of a narrow silicon steel sheet core and a large hollow or through-hole shaft.

Similar to linear motors, torque motors are “frameless” motors. This means that the motor has no housing, bearings or measuring system. These components are selected by the machine builder according to performance requirements or purchased as a package.

Torque motors produce high torques at medium speeds, even at standstill or at zero speed. Unlike conventional motors, torque motor specifications and selection depend primarily on torque, not power. Furthermore, peak torque determines the maximum torque that the motor can actually produce, and continuous torque determines the torque that the motor can deliver continuously. The load cycle of the application determines the degree of dependence on either peak or continuous torque.

The difference between servo motor and torque motor

I. Different performance

1) Servo motor: can make the control speed, positional accuracy is very accurate, can be converted into voltage signal torque and speed to drive the control object. Servo motor rotor speed is controlled by the input signal, and can respond quickly, in the automatic control system, used as an executive element, and has a small electromechanical time constant, high linearity, starting voltage and other characteristics.

2) Torque motor: a kind of special motor with more poles, it can run continuously even when the motor is in low speed or even blocked (i.e. the rotor can’t rotate), and it won’t cause damage to the motor. And in this working mode, the motor can provide stable torque to the load.

II. The principle is different

1) Servo motor: so that the object’s position, orientation, state and other output controlled quantities can follow the input target (or given value) of the arbitrary changes in the automatic control system. Servo mainly rely on the pulse to position, basically can be understood in this way, the servo motor receives a pulse, it will rotate a pulse corresponding to the angle, so as to realize the displacement.

2) Torque motor: torque motor allows long-term low-speed operation (or even blocking immobilization), its heating is very serious, usually using an external blower forced air-cooled. When using the torque motor, attention should be paid to check whether the blower is running well or not, and its surrounding should have good ventilation environment, and dry flammable materials are not allowed. Flammable dust or volatile combustible oil type, etc. are close by.