Axial Flux Permanent Magnet Motors

why choose us

DJ Edrive Is A Professional Industrial Drive System Solution Provider, Dedicated To Providing High-Efficiency Permanent Magnet Motor Drive Solutions For Industrial Customers Around The World.

what we do

Our Best Solutions

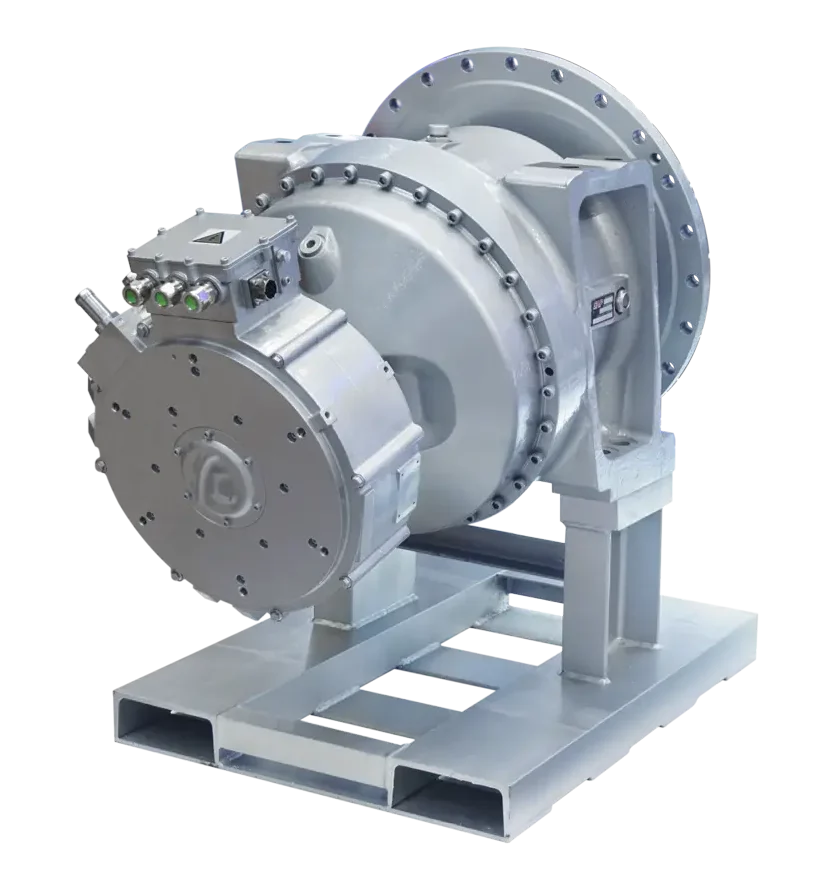

Axial Flux Motors in Upper-Loading systems

Slim and compact, High efficiency and energy saving

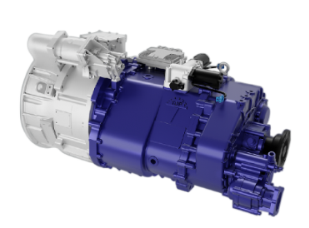

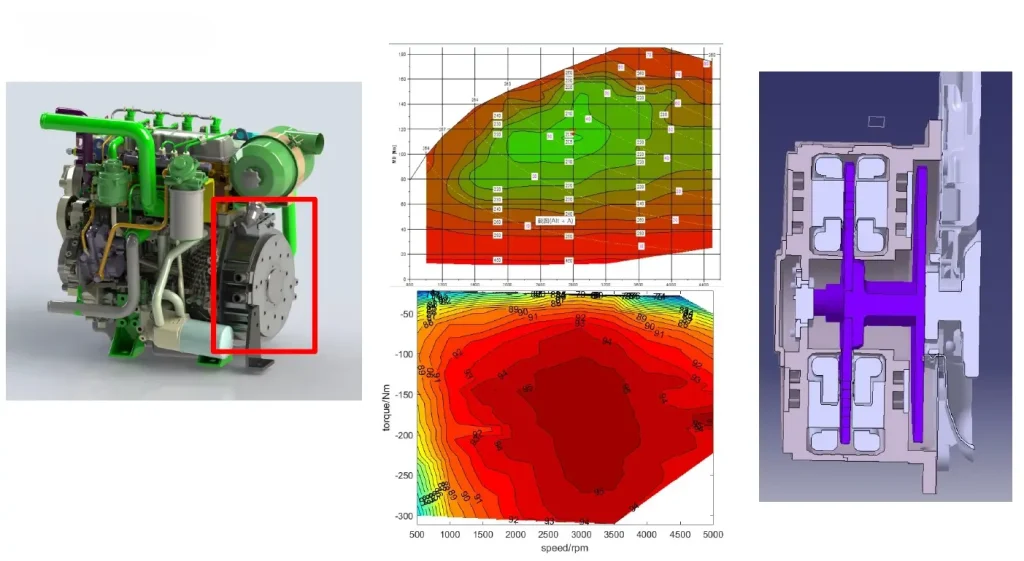

Axial Flux Motors In Hybrid Systems

Lightweight structure, High efficiency and energy saving

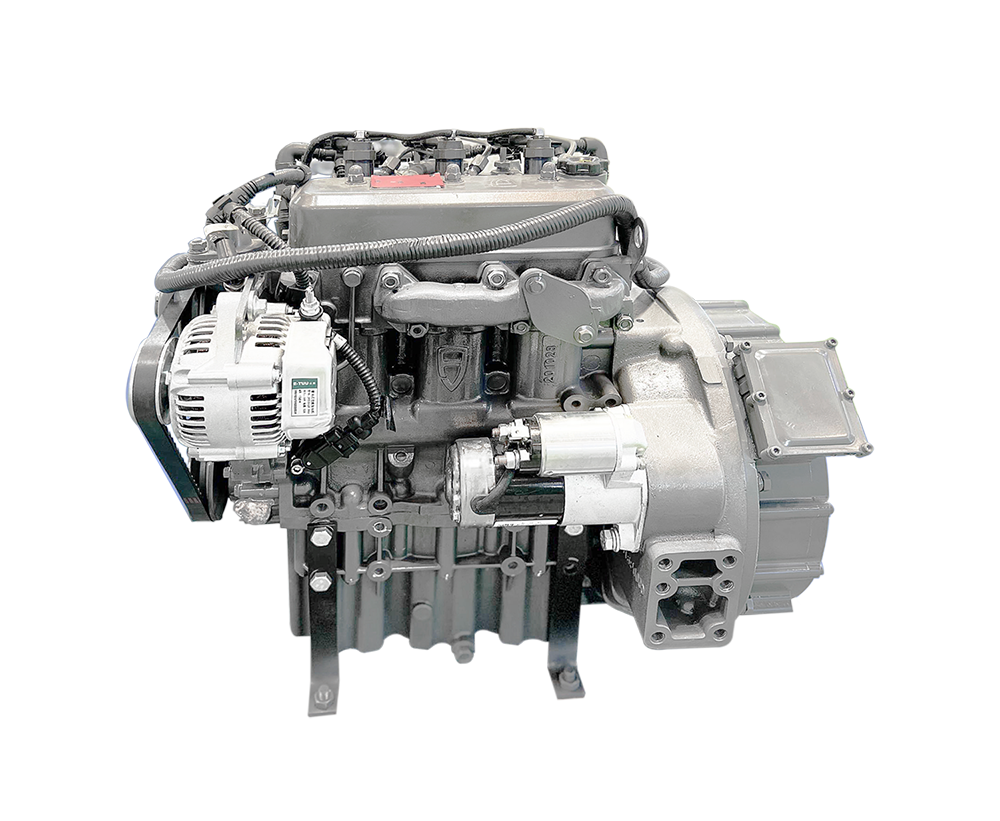

Axial Flux Motors In Generator Sets

Silent operation, Simplified structure and easy maintenance

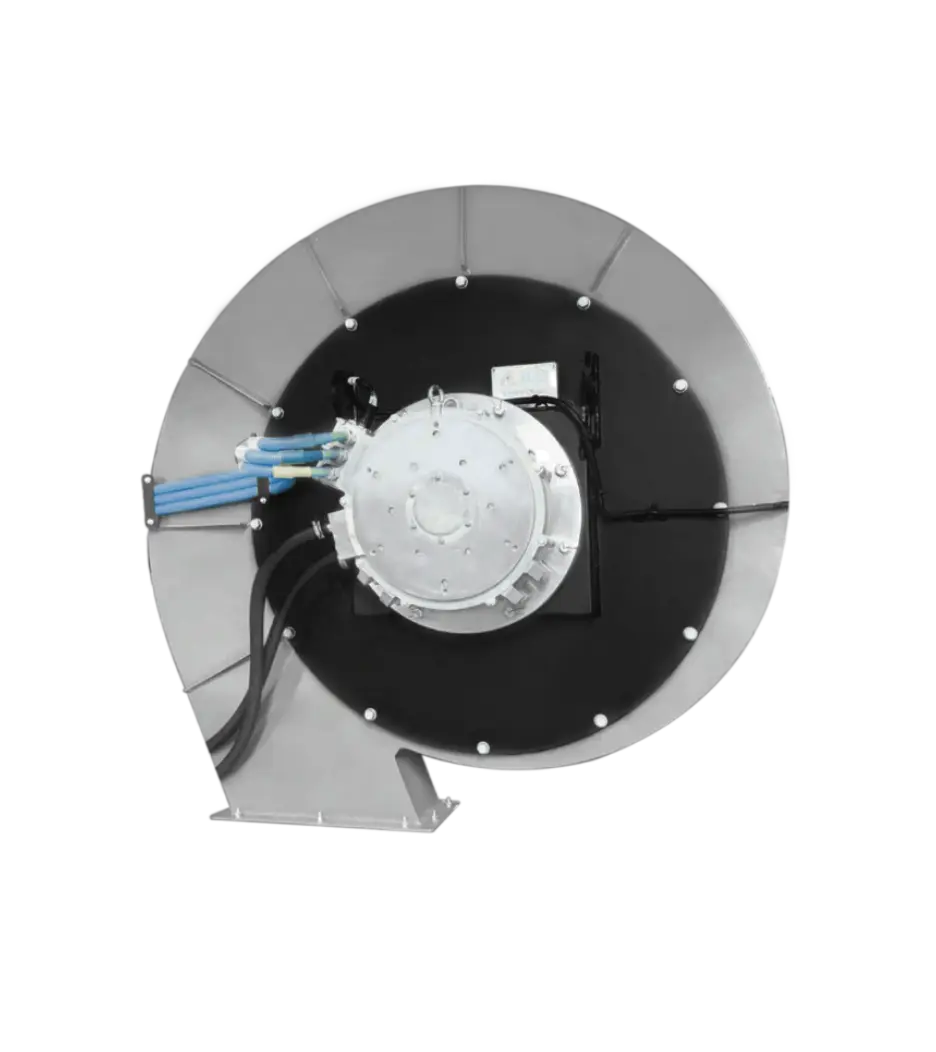

Axial Flux Motors In Range Extender

Space saving, Low speed and high torque,Customizability

Axial Flux Motors In electric vehicles

Slim and compact, High efficiency and energy saving

Axial Flux Permanent Magnet Motors

Axial flux permanent magnet motors, also known as disk-type permanent magnet motors, are gaining more and more attention due to their compactness, high efficiency and high power density. They are particularly suitable for applications such as electric vehicles, renewable energy systems, geared energy storage systems and industrial equipment where high torque density and compact space are required.

Adhering to the concept of “energy saving and emission reduction, green energy”, relying on self-developed axial magnetic field permanent magnet synchronous motor products, combined with its technological advantages and product characteristics, around the four major systems of range extender, hybrid system, top-mounted drive system and generator set products, forming four motor product lines.

Relying on self-developed axial magnetic field permanent magnet synchronous motor products, it has formed a unique performance advantage integrating energy efficient, ultra-thin and ultra-light, high torque density, module integration and other characteristic advantages, with a maximum efficiency of 97% or more, and an area of high efficiency (efficiency > 90%) of more than 90%.

In the past three years, we have realized successful application and batch supply in many fields, such as range extender system, hybrid system, top-loading system, generator set, etc., and have achieved milestone application results in the field of construction machinery, such as cement mixer trucks, and have occupied 30% of the market share in certain market segments.

Product features

High efficiency and energy saving

Efficiency up to 97% or more, high efficiency (efficiency > 90%) area of 90% or more

Ultra-thin and light

Flat structure, short axial dimensions, light weight to meet the needs of vehicle light weighting

Low speed and high torque

Disk rotor design for high torque output, easy to achieve high torque density

Module Integration

Modular product design, expandability, and enhanced fault tolerance

Manufacturing capabilities

Punching and coiling at one time with precise servo control;

Simple punching molds, fast capacity increase;

High material utilization, cost control.

Automatic glue mixing and injection, precise control of dosage;

Vacuum potting, clean and environmentally friendly;

Good insulation, high strength, high reliability.

Carbon fiber wet winding technology to improve rotor strength;

Integral rotor magnetization technology, reducing the difficulty of assembly.

Automated assembly, high product yield;

Digital management, intelligent manufacturing;

Traceable products, replicable capacity.

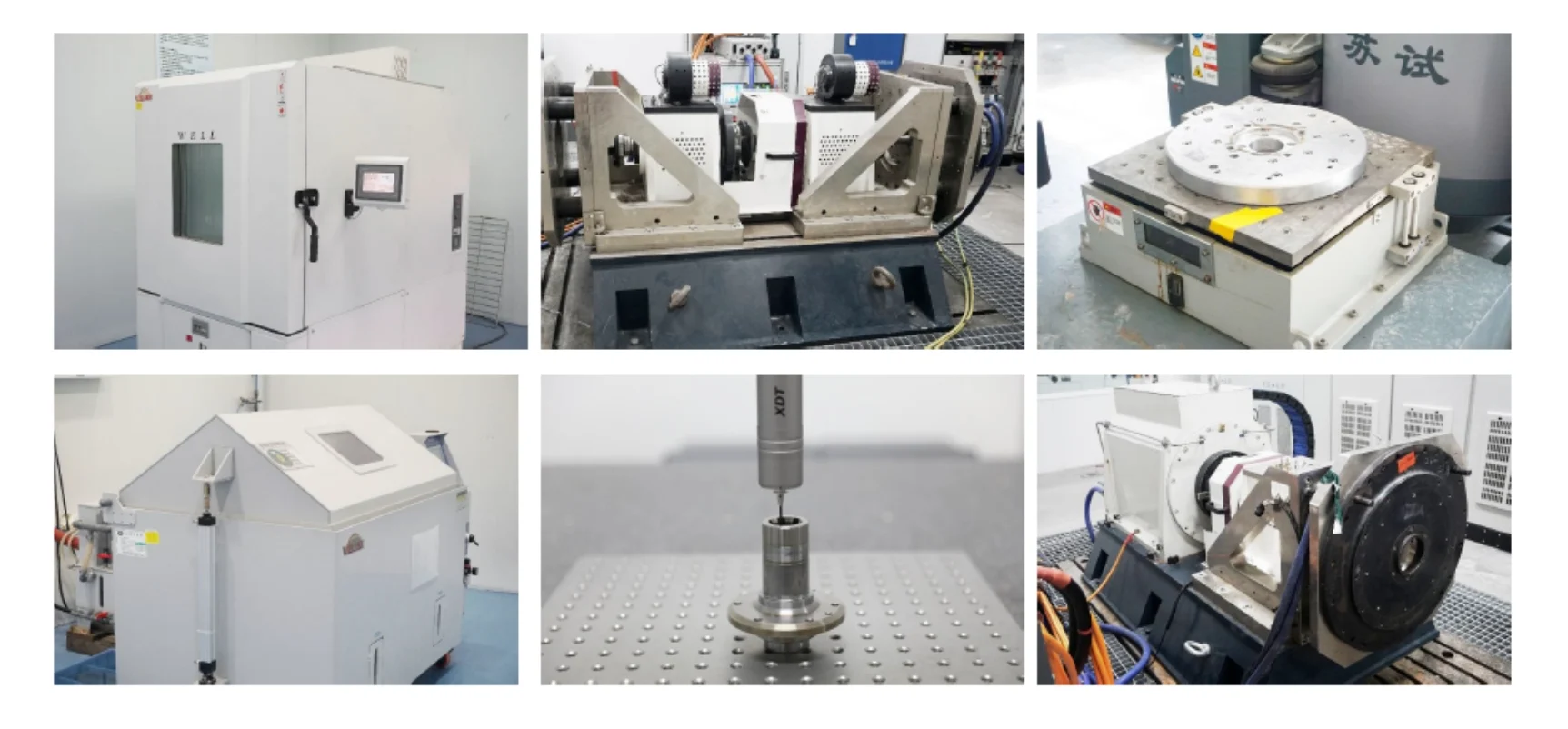

Test capabilities

General Items

Appearance, dimensions, quality, strength, sealing, insulation withstand voltage, electrical properties

Input/Output Characteristics

T-n Characteristics, T-P Characteristics, Electric Characteristics, Feeder Characteristics, Efficiency, System Specifications, Control Accuracy

Environmental adaptability

High Temperature, Low Temperature, Salt Spray, Humidity, Protection Rating, Vibration

Safety

Safe grounding, protective function

Reliability

Durability test, Impact test

our Customers