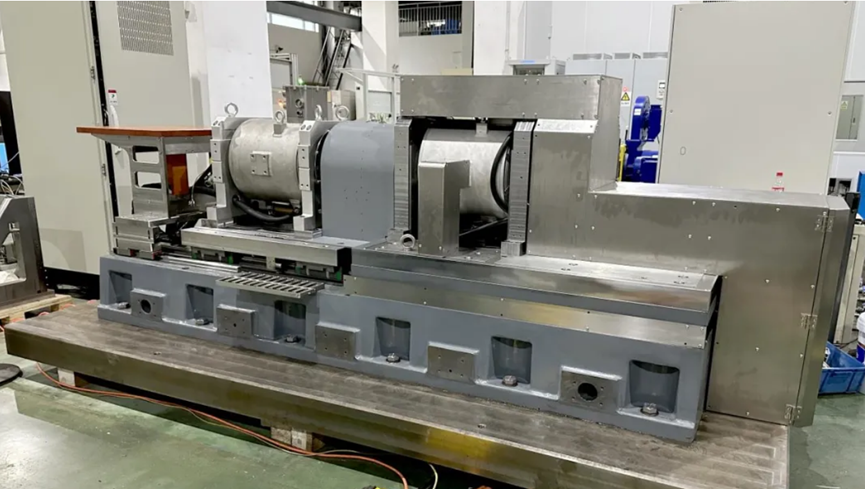

36,000RPM High-Speed Motor and Full-Scale Test System Revealed

1.Motor calibration

MAP diagram, temperature rise, no-load loss, control accuracy, endurance test, reverse electromotive force, overspeed test, external characteristic diagram, etc.

2.Sensor system monitoring

Full-scene safety interlock sensing of movable parts, full-scene navigation operating system based on sensors, online real-time monitoring system based on vibration sensing and temperature sensing.

3.Rotor dynamics test

Motor rotor rotor dynamics testing, modal vibration testing, sliding bearing axial trajectory testing and analysis, rolling bearing/bearing fault diagnosis and analysis, rotor dynamics experiments, motor development experiments, vibration mapping analysis, expert diagnostic system, fault prediction.

4.Automatic Coaxiality Alignment System

Based on the high-precision micrometer sensor development of on-line, thinking-free animation navigation type alignment system, manual or automatic mode, the measurement accuracy of up to 0.01μm, alignment accuracy of up to 5μm.

5. Non-contact temperature measurement of microvia rotor

Real-time monitoring of rotor temperature for high-speed running motors, which can truly measure the rotor temperature value and accurately monitor the temperature rise status of the motor during high-speed operation.