What is the appropriate slot fullness of the motor winding, and is it better to have a higher slot fullness?

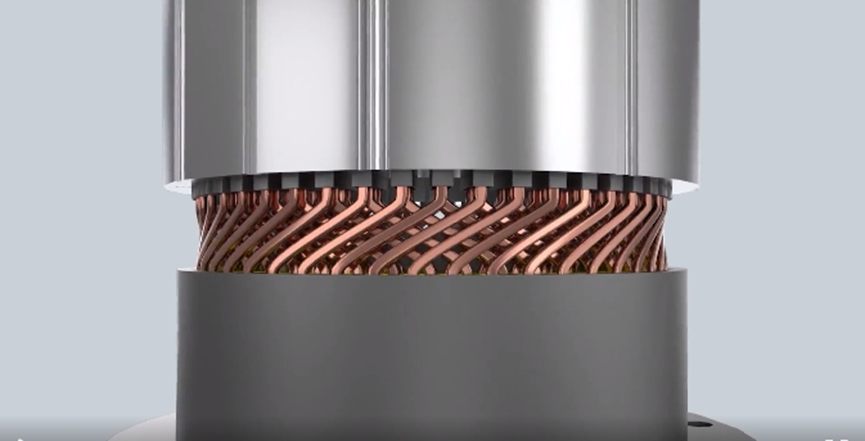

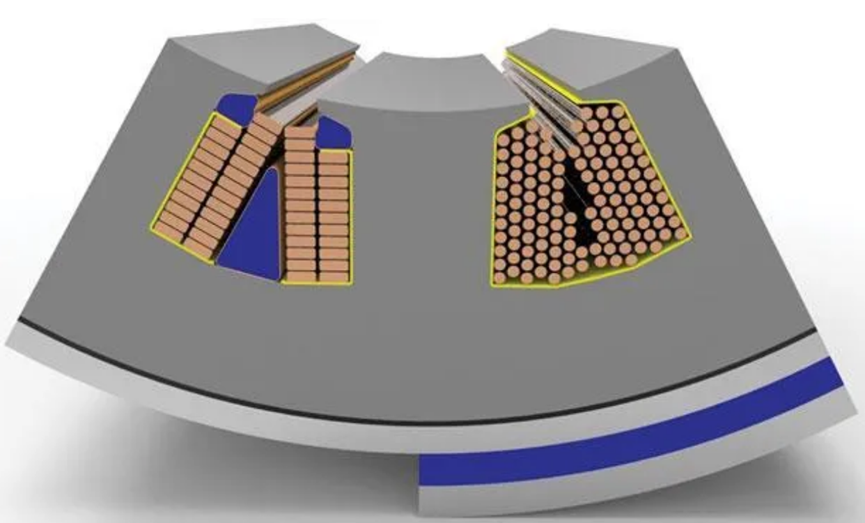

The stator slot fullness of a motor refers to the proportion of the stator slot occupied by the windings. When designing a motor, the stator slot filling ratio will directly affect the performance of the motor, but it does not mean that the higher the better. In this paper, we will analyze the significance and influencing factors of the stator slot fullness rate of the motor from different perspectives, and summarize the most suitable stator slot fullness rate. First of all, the stator slot filling rate has a direct impact on the performance of the motor. When the stator slot fullness is high, the area occupied by the windings is large, resulting in a shorter stator winding length, which reduces resistance and losses. This improves the efficiency and power factor of the motor and reduces energy consumption. In addition, a high stator slot fullness also reduces the gaps in the stator windings and increases the degree of embedding of the stator in the rotor, thereby increasing the output torque and power density of the motor. Therefore, from the performance point of view, high stator slot fullness is advantageous.

However, too high a stator slot fullness also brings some problems. The first is the increase in manufacturing difficulty. In the design and manufacturing process, the higher the stator slot fullness, the higher the requirements for winding compactness and insulation, which will increase the manufacturing difficulty and cost. Next is the heat dissipation problem. High stator slot fullness will reduce the ventilation space of the stator slot, resulting in difficult heat dissipation of the windings, and the high temperature rise may cause the insulation material to deteriorate, reduce the life of the motor, or even burn accidents. In addition, high stator slot fullness will also increase the vibration and noise of the motor, affecting the smoothness and reliability of the motor.

Therefore, after weighing the above factors, a reasonable stator slot fullness rate should take into account a number of factors. Specifically, it mainly includes the following aspects:

1. Magnetic circuit design: The magnetic circuit design of the motor is an important factor affecting the stator slot filling ratio. Through the use of suitable magnetic circuit structure and winding arrangement, the number of stator slots can be reduced without reducing performance, thus improving the stator slot filling rate.

2. Heat dissipation design: Heat dissipation is an important issue in the case of high stator slot fullness. Therefore, it is necessary to consider the design of radiator and ventilation system in the design to ensure the heat dissipation ability of the motor when running.

3. Structural design: The structural design of the motor is closely related to the stator slot fullness. Reasonable design of stator slot geometry and size can maximize the use of stator slot space and improve stator slot fullness under the premise of meeting performance requirements.

4. Insulation design: High stator slot fullness requires more insulation, so the selection of insulation materials and the design of winding insulation need to be considered to ensure that the motor does not fail during operation.

In summary, the level of stator slot fullness of a motor has a direct impact on motor performance. Too high or too low stator slot fullness will bring negative impacts, therefore, when designing the motor, it is necessary to comprehensively consider a number of factors, including magnetic circuit design, heat dissipation design, structural design and insulation design, etc., in order to realize the optimal stator slot fullness. Only after comprehensively considering the performance of the motor, manufacturing difficulty, heat dissipation conditions and reliability, etc., can the most appropriate stator slot fullness be determined to meet the requirements of the motor design, so as to achieve the purpose of optimizing the performance of the motor.